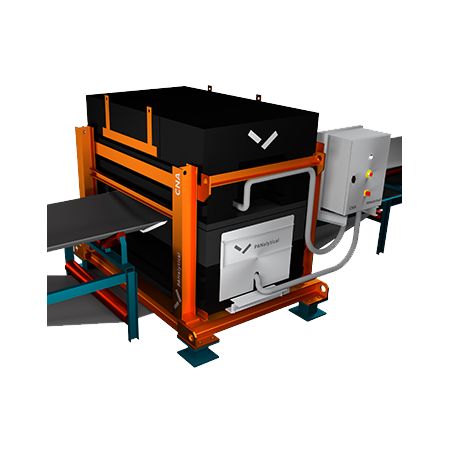

CNA™ Pentos-Cement

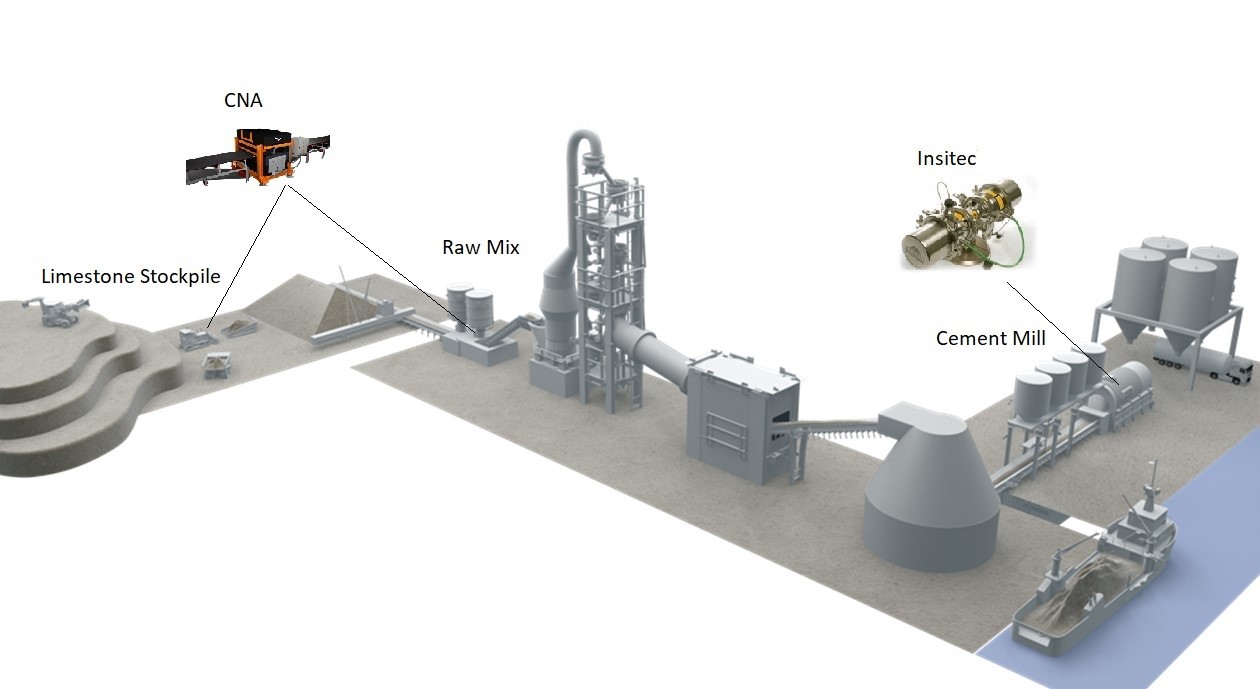

เป็นเครื่องวิเคราะห์หาชนิดและปริมาณของธาตุต่างๆ ที่อยู่ในวัตถุดิบสำหรับการผลิตซีเมนต์ เพื่อตรวจเช็คคุณภาพของวัตถุดิบก่อนที่จะเข้าสู่กระบวนการผสม โดยที่เครื่อง CNA™ Pentos จะติดตั้งอยู่ที่สายพานลำเลียงวัตถุดิบ ตรวจวิเคราะห์และส่งผลแบบเรียลไทม์ ไม่ต้องมีการเตรียมตัวอย่าง และไม่ทำลายตัวอย่าง เทคโนโลยี Pulsed Fast and Thermal Neutron Activation (PFTNA) เป็นเทคโนโลยีที่ทันสมัยและปลอดภัยที่สุดในการตรวจวัด โดยหลอดกำเนิดนิวตรอน (Neutron Tube) มีแหล่งกำเนิดรังสีที่มาจากธาตุไฮโดรเจน-3 (ทริเทียม) จะทำงานและแผ่รังสีก็ต่อเมื่อเครื่องทำงานและจ่ายกำลังไฟฟ้าให้เท่านั้น สามารถควบคุมการผลิตนิวตรอนได้ ง่ายและปลอดภัยต่อผู้ใช้งานเวลาถอดเปลี่ยนหลอดนิวตรอน CNA™ Pentos-Cement เป็นรุ่นที่ห้าของเครื่องวิเคราะห์ธาตุบนสายพานแบบออนไลน์ที่ทันสมัยที่สุดในโลก ด้วยเทคโนโลยี Pulsed Fast and Thermal Neutron Activation (PFTNA) ที่พัฒนามาเรื่อยๆอย่างไม่หยุดยั้ง ทำให้ตอบโจทย์ความท้าทายยุคปัจจุบันได้เป็นอย่างดี

ในรุ่นที่ 5 นี้ มีอะไรดีกว่ารุ่นเดิมบ้าง

CNA™ Pentos-Cement ทำให้การวิเคราะห์ธาตุจำนวนมากหรือวัตถุดิบที่ขนส่งมาทางสายพาน ทำได้อย่างรวดเร็ว เรียลไทม์ ส่งผลให้กระบวนการผลิตทำได้อย่างมีประสิทธิภาพมากขึ้นกว่าเทคนิคอื่นๆ เมื่อวัตถุดิบผ่านการควบคุมคุณภาพ ความเสถียรและการควบคุมเตาเผา จะทำได้ง่ายยิ่งขึ้นกว่าที่เคย ไม่จำเป็นต้องสุ่มตรวจ หรือหยุดไลน์การผลิต อันนำมาซึ่งความสูญเสียในแง่ของการรอคอยและจากกระบวนการผลิต (Delay & Processing)

Contact US Download Brochure